With the increasing demand for more sustainable energy, renewable energy development along with lithium-ion batteries is moving rapidly. With several advantages possessed by batteries such as high-power density, small size, relatively long lifespan, and low self-discharge rate, batteries are very popular for use in electronic devices, electric cars, energy storage, and even the aviation industry. Electric cars are beginning to grow in Indonesia, with 10,000 BEVs in 2022 compared to only 600 BEVs in 2021. As for electric motorcycles, around 887,000 2WEVs were in circulation in Indonesia in 2021, up from 535,000 in 2020. On the other hand, there is a growing battery market demand, as seen from the development of battery manufacturing and testing facilities. For example, CATL has invested 6 billion dollars to establish an integrated battery processing factory, which includes nickel and cobalt mining and extraction, battery material production, battery cell manufacturing, and battery recycling systems.

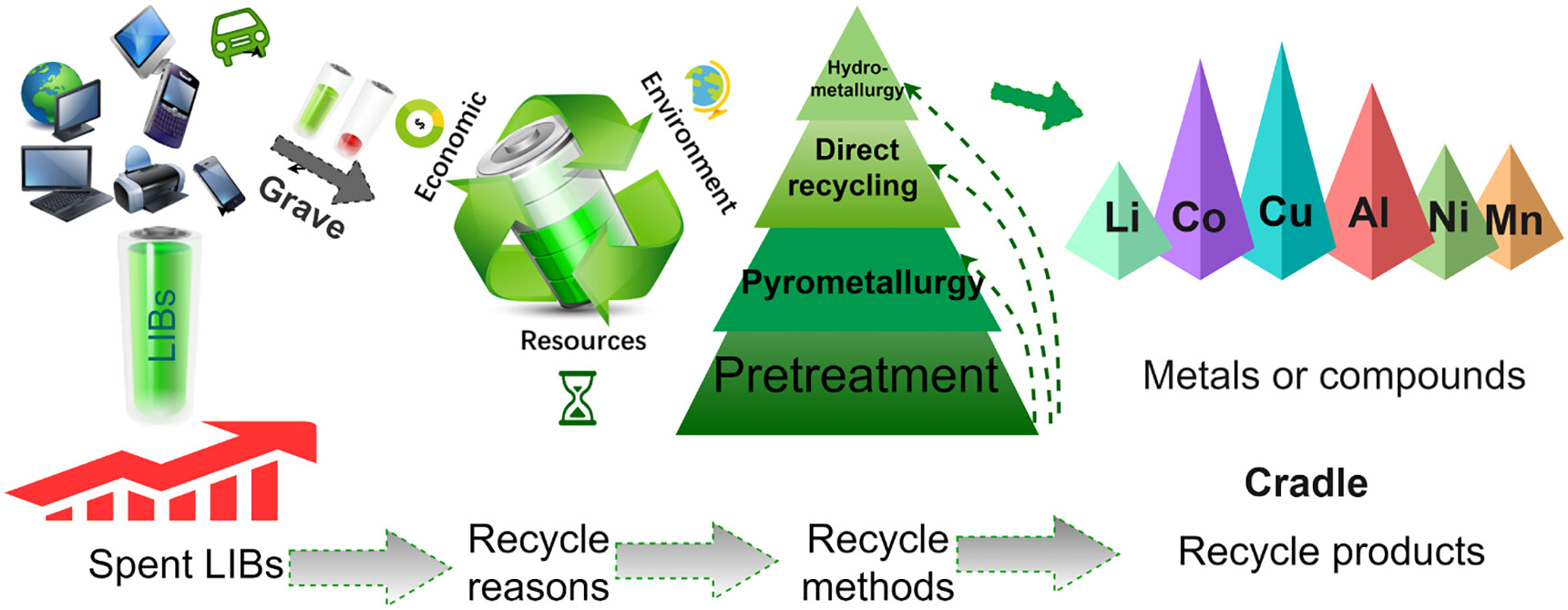

Lithium-ion batteries contain valuable and high-demand critical metals such as nickel, cobalt, manganese, and lithium. With the depletion of nickel and cobalt mineral resources and the absence of a commercially scalable lithium extraction process in Indonesia, recycling of spent batteries can help feed nickel, cobalt, manganese, and lithium metals back into the system, thus promoting a circular metal economy. Batteries can be recycled through various processing routes, such as pyrometallurgy, hydrometallurgy, physical separation, or combination of several processes.

Du, K., Ang, E.H., Wu, X. and Liu, Y. (2022), Progresses in Sustainable Recycling Technology of Spent Lithium-Ion Batteries. Energy Environ. Mater., 5: 1012-1036. https://doi.org/10.1002/eem2.12271

The pyrometallurgical route involves high temperatures to reduce easily reducible metal oxide components into metal alloys. The pyrometallurgical route system can recycle multiple types of batteries simultaneously without the need for pretreatment stages. However, due to its high operating temperature requirement, this route demands significant external source of energy. The hydrometallurgical route employs aqueous solutions to leach metals from cathode metal oxides. This route yields high product purity but generates substantial liquid waste. The physical separation route can preserve the physicochemical properties of the active materials and requires less energy. A drawback of the direct separation route is that it can only process one type of battery to maintain the purity of the recovered active material. Several processes that have successfully retrieved metals from spent lithium-ion batteries include Retriev process (mechanical separation), Lithorec process (hydro-pyrometallurgy), Recupyl process (physical separation & hydrometallurgy), Batrec Industrie AG (hydrometallurgy), and Umicore (pyrometallurgy).

| Date | : | 29 August 2023 |

| Written by | : | NBRI |

| Share Article | ||